OPICO inter-row cultivators are designed to accurately hoe between rows of growing crops to cut off the weeds just below the surface.

Download the brochure here: OPICO Mechanical weeding Interrow cultivating (fliphtml5.com)

Almost any crop with adequate space between the rows can be tackled. Inter-row cultivators are fully adjustable and configured to suit any row width or combination of row widths. Front or rear-mounted versions are available, along with trailed semi-mounted versions.

With many options available, creating a bespoke mechanical weeding machine requires technical expertise and know how. The process begins with a farm visit to understand the needs and any issues e.g. crop type, soil type, how the crop is grown, how high tech or low tech a solution is being sought.

After this initial visit a proposal is prepared recommending headstock type, share type, guidance system and other installation options. Once the bespoke specification is agreed, OPICO works closely with the factory to deliver and then install and support the machine.

FEATURES & BENEFITS

Configurations are endless!

- Suitable for combinable, root, salad and specialist crops

- 3m to 18m working widths

- 4 to 72 rows

- Front or rear mounted

- Fully or semi-mounted

- Manual, mechanical or camera-guided steering

- Available with seed or fertiliser application equipment

Heavy Duty Parallelograms

Parallelogram mounting frames for the hoe carriers maintain pre-set working angles and pressure whilst allowing accurate ground contour following.

Different numbers of shares are fitted to the hoe carriers depending on row widths and crop types, for example in cereal crops 3 rows are hoed per carrier with a minimum row spacing of 12.5cm.

- Box section parallelograms

- No twisting in work

- Bushed pivots

- Greased adjustable depth wheels

Steel Flange Wheel

Moving the hoe shares sideways to follow plant rows creates powerful lateral forces.

If side forces exceed grip from the tractor’s rear wheels, then the tractor could be moved sideways leaving the hoe position unchanged resulting in damage to the crop.

To prevent this, the headstock has a pair of large diameter flanged steel wheels which anchor the guidance headstock in line behind the tractor wheels. Thereby withstanding the side forces for perfect row following.

This is particularly the case with wider working widths, or when the hoe shares are working deep.

Bespoke Tube Profile

Hatzenbichler’s bespoke tube profile and locking mechanism ensures machines can be configured as required and all components are locked in position.

Spot Spraying

The camera software developed by Tillet and Hague allows for the addition of spot spraying technology to be attached to the cultivator if required.

Tillett and Hague are world leaders in the development of vision guidance and control technology for field scale precision crop protection, whether mechanical, chemical or biological.

GUIDANCE SYSTEM

The objective of camera steering is for mechanical weeding to be more accurate, efficient and easier for the operator. It requires a precisely engineered headstock for exact movement control, allowing the operator to work more effectively at higher working speeds. Camera guided machines can be operated much closer to the plant rows and hence provide improved weed control.

Isobus Section Control

To bring an extra level of precision there’s also the option of ISOBUS controlled sprayer-style GPS section control.

With individual hydraulic rams on each parallelogram linkage, the Muller ISOBUS controller is able to lift individual row units as they reach previously cultivated ground.

This is a particular benefit when working in fields with angled headlands – the system is able to detect when the hoe shares are reaching the end of the run and automatically lift them out of work to avoid hooking out plants on the cross-drilled headland bouts.

INTER-ROW MODELS

Combinable Crops 12.5cm - 30cm (Example)

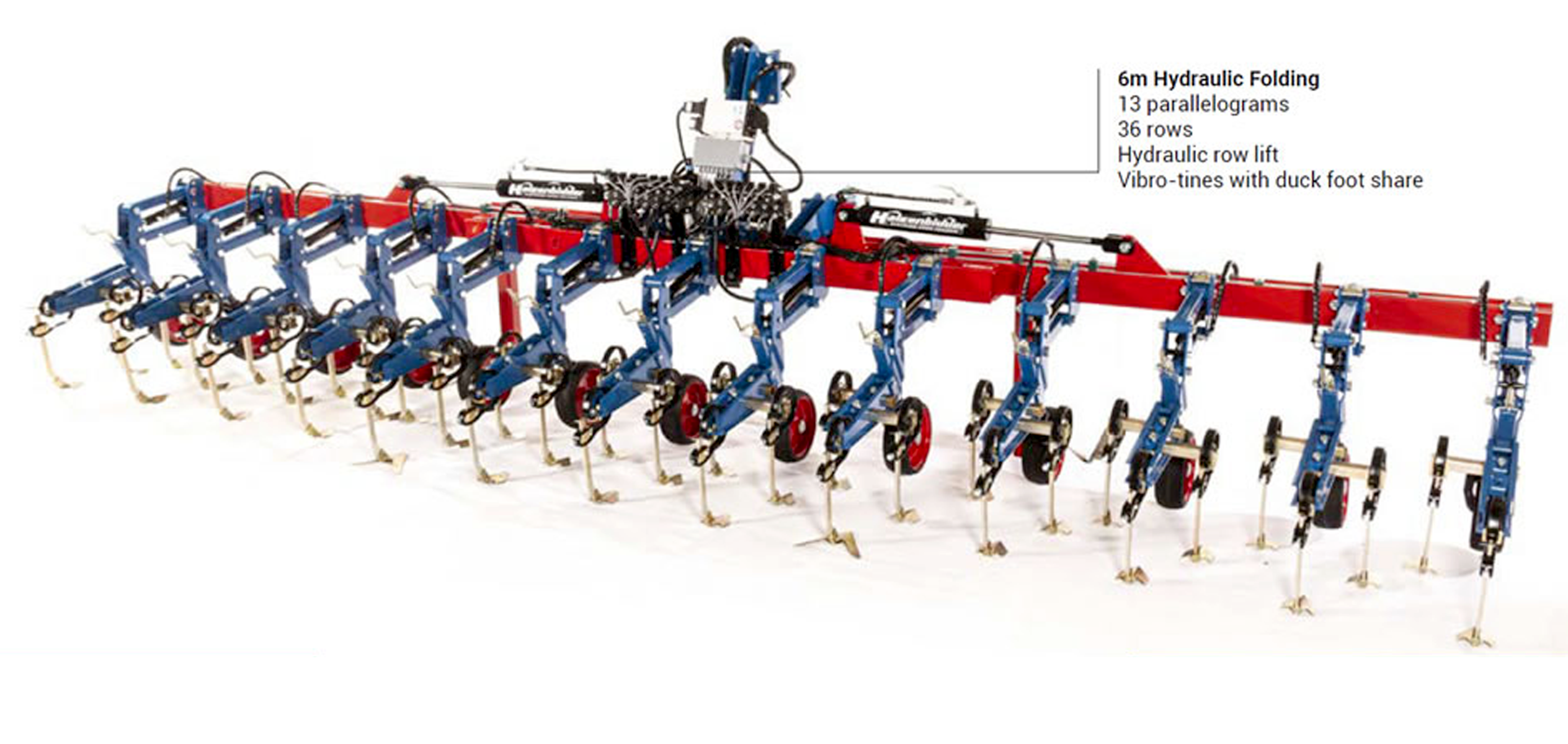

The Hatzenbichler range of rigid and hydraulic folding inter-row cultivators, are typically used for combinable crops and are available in 3 – 18m working widths. Row widths from 12.5cm to 30cm, can be cultivated.

The machines can be mounted to the front or rear of the tractor. The hoe carrier is fitted as standard with Vibro-tines and duck foot shares.

- 3m to 18m

- Front or rear mounted

- 1, 3 or 5 section frame

- 1 or 3 tines/parallelogram

- 12.5cm row spacing upwards

- Vibro-tine with duck foot share

EXAMPLE: Cereal cultivator at 25cm spacing and 16.6cm spacing

Model No. Rows Working Width Parallelo-grams HP Weight 17478103 16 4m 6 80 1200kg 174781021 24 4Mm/6m 9 120 1800kg 174781026 36 6m 13 160 2700kg 174781025 32 8m 12 150 2400kg TBC 48 8m 17 TBC TBC

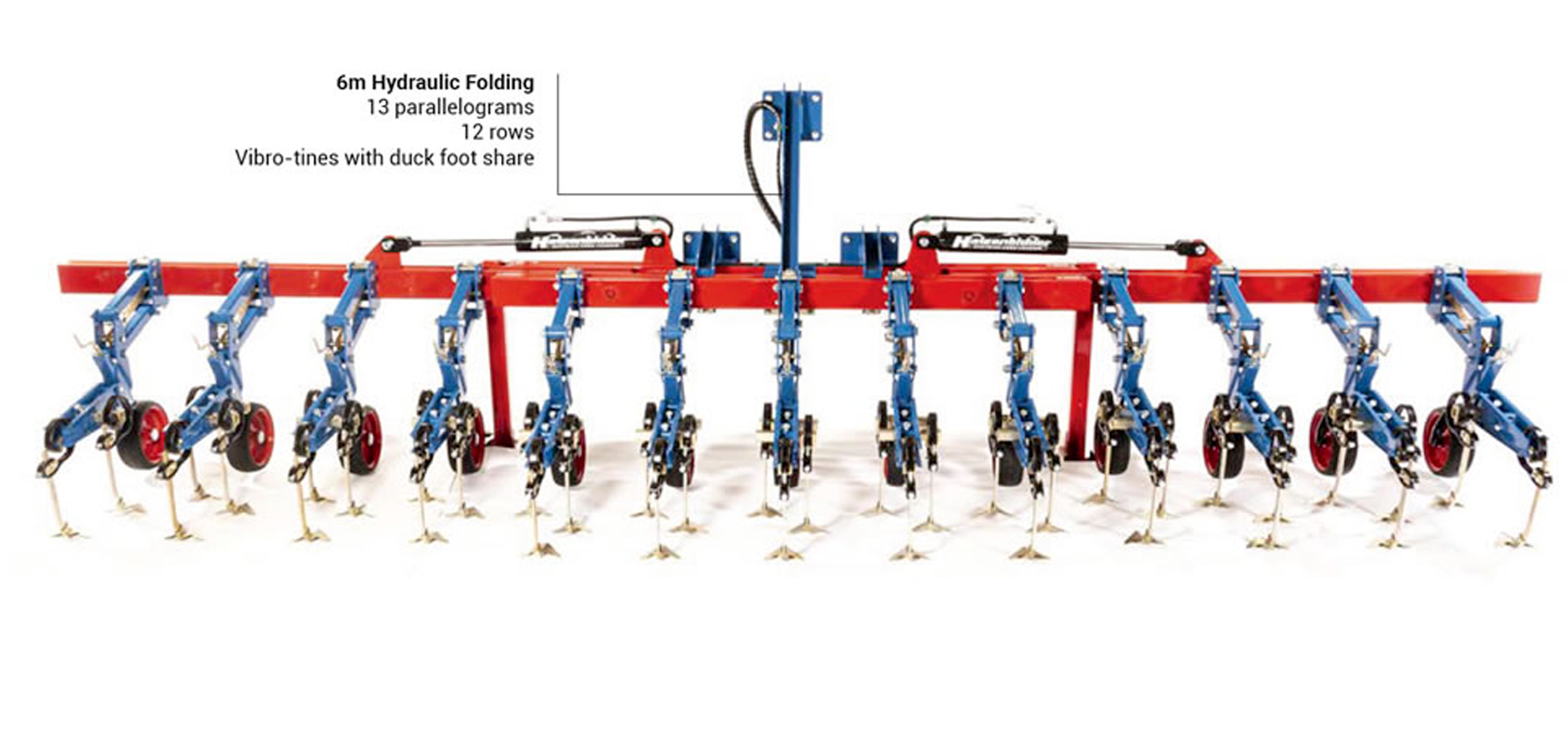

Sugar Beet 35cm - 50cm (Example)

The Hatzenbichler range of rigid or hydraulic folding inter-row cultivators, are typically used for sugar-beet and are available in 3 – 12m working widths.

The Inter-row is also suitable for other crop types at similar spacing. Row widths can be set between 35cm and 50cm.

The machines can be mounted to the front or rear of the tractor. The hoe carrier is fitted as standard with Vibro-tines and duck foot shares.

- 3m to 12m

- Front or rear mounted

- 1, 3 or 5 section frame

- 3 tines/parallelogram

- 35cm to 50cm spacing

- Vibro-tine with duck foot share

EXAMPLE: Sugar Beet cultivator at 50cm spacing

| Model No. | Rows | Working Width | Parallelo-grams | HP | Weight |

| 8 | 4m | 9 | 60 | 770kg | |

| 1742810 | 12 | 6m | 13 | 75 | 810kg |

| 16 | 8m | 17 | 110 | 1390kg |

The Hatzenbichler range of rigid or hydraulic folding inter-row cultivators are typically used for maize and are available in 3m to 12m working widths. Row widths can be set from 50cm upwards.

The machine can be mounted to the front or rear of the tractor. The hoe carrier is fitted as standard with S-tines and A shares at 150mm wide and half shares at 85mm wide.

The maize inter-row cultivator is designed to hoe the weeds and/or bury them depending on growth stage.

- 3m to 12m

- Front or rear mounted

- 1, 3 or 5 section frame

- 3 or 5 tines/parallelogram

- 50cm row spacing upwards

- S-tine with A share

EXAMPLE: Maize cultivator at 75cm spacing

| Model No. | Rows | Working Width | Parallelo-grams | HP | Weight |

| 1741670 | 6 | 4.5m | 7 | 60 | 800kg |

| 1741680 | 8 | 6m | 9 | 80 | 920kg |

| TBC | 10 | 7.5m | 11 | 110 | 1460kg |